How Palletization for U.S. DCs Saves Camping Furniture from China?

The first time a U.S. DC refused my pallets, I felt sick. One truck. One bad pallet pattern. One month’s margin gone. Would you take that risk when a 40×48 GMA, corner boards, edge rails, a clear GS1-128 carton label plan, and a simple ISTA 3E check can prevent it?

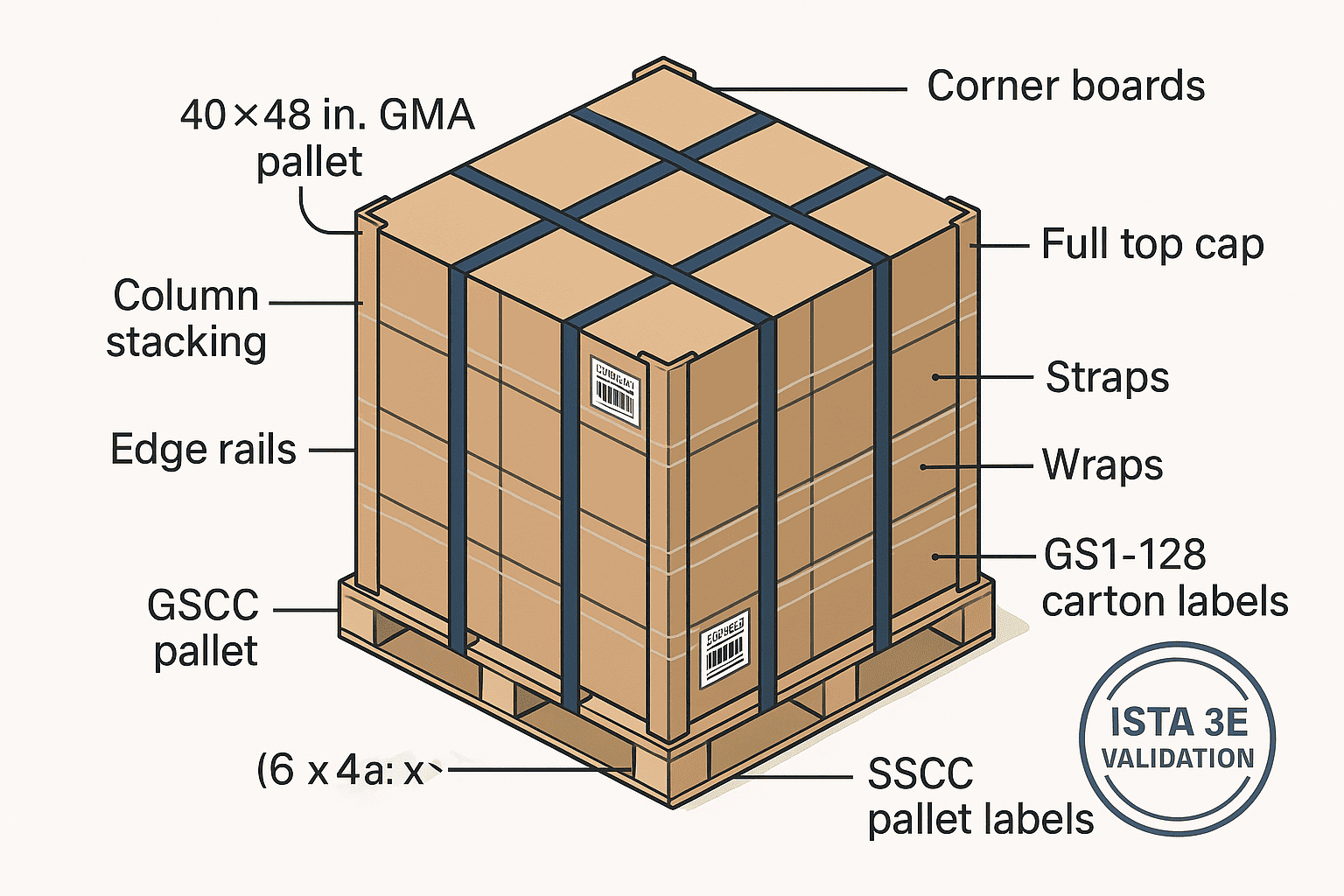

Use a 40×48 in GMA pallet with no overhang, column stacking, corner boards and edge rails, a full top cap, four straps plus six wraps, GS1-128 carton labels, SSCC pallet labels, and validate the pallet pattern with ISTA 3E before scale-up.

I write this for buyers who ship camping chairs, foldable tables, and folding camp cots from China into Walmart, Target, Costco, Amazon, or 3PL DCs. I have stood at the clamp dock, watching a stack lean, praying it survives. I have also stood there later, calm, because the palletization was correct. My goal is simple: you feel the second moment every time.

I want you to ship once, invoice once, and sleep at night. Here is the path we will follow—clear, simple, proven:

-

Start with the pallet. Bad wood ruins good cartons. We lock 40×48 GMA, 4-way, A-grade.

-

Fix the cartons. No overhang, no mixed heights, column stack for strength.

-

Publish the pallet pattern. Tie×High, strap paths, and wrap count so no one guesses.

-

Make labels scan first time. GS1-128 on cartons, SSCC on pallets, grade C or better.

-

Handle retailer twists. Amazon, Walmart, Target, Costco, and 3PL rules baked into the spec.

-

Prove it once. ISTA 3E compression, vibration, and tilt to kill debates later.

-

Use a do/don’t list. Edge rails, corner boards, bagged feet; never let straps bite.

-

Know refusal triggers. ASN mismatches, overhang, leaning, dirty pallets, weak barcodes.

-

Put rules in the PO. Short copy-ready clauses so teams follow them on every shift.

Follow these steps and your freight clears U.S. DCs—and your margins live.

What Pallet Hardware Spec Works for Palletization in U.S. DCs (GMA 40×48, HT, A-Grade)?

Bad pallets bend. Bending makes stacks lean. Leaning invites clamp damage and refusals. The fix is a clean, strong base that matches U.S. dock gear and fork habits.

Lock 40×48 in (1016×1219 mm) GMA pallets with true 4-way entry, seven top deck boards, sound stringers or blocks, visible HT stamp, ≥2,000 lb static capacity, and A-grade condition. Switch to CHEP/PECO/iGPS only when the buyer mandates it.

Palletization for U.S. DCs—Hardware Checklist with Target Keywords

- I start with a fast pallet inspection. Anything that fails is rejected.

- Size & entry: Confirm 40×48 in GMA with true 4-way entry for clamp trucks and jacks.

- Deck boards: Count 7 top boards; no breaks, warps, or loose pieces.

- Surface check: Feel for splinters and oil; pallets must be clean and dry.

- Export mark: Verify the HT stamp (heat-treated) is clear and legible.

- Structure: Tap stringers/blocks; wood must sound solid, not hollow or cracked.

- Capacity: Require ≥ 2,000 lb static rating before loading camping furniture.

- Safety edges: Look for flush nails and no sharp edges that can cut stretch wrap.

- Program pallets: For CHEP/PECO/iGPS, get buyer approval in writing and add it to the PO.

- Decision rule: Simple pass/fail at the dock—if any item fails, swap the pallet.

These clear checks keep cartons safe, stacks straight, and DCs happy.

| Item | Pass | Fail |

|---|---|---|

| 40×48 GMA (palletization for U.S. DCs) | 4-way, HT, 7 boards | Odd size, 2-way, no HT |

| Condition (A-grade) | Clean, dry, no cracks | Oil, mold, broken boards |

| Nails & edges | Flush, smooth | Protruding, sharp |

| Capacity | ≥2,000 lb static | Unknown/low rating |

| Program pallets | Buyer-mandated only | Unapproved swap |

Why Carton Rules, Edge Rails, and Corner Boards Stop Leaning and Crush for Camping Furniture Manufacturers in China?

Leaning starts small. It ends with crushed corners and chargebacks. Corner boards resist clamp pressure. Edge rails stop tube ends from cutting into corrugate. Overhang kills everything.

Keep every carton inside the pallet edge by ≥0.25 in, use column stacking for compression, fix uniform heights per layer, add U-channel edge rails on exposed edges, run full-height corner boards ≥3 mm, and top with a 40×48 double-wall cap.

Edge Rails, Corner Boards, and Pallet Pattern—Practical Rules with Target Keywords

With the pallet foundation set, I protect every carton where metal meets paper:

- Protect metal-to-paper contact. Anywhere tubes or metal meet corrugate needs protection.

- Edge rails: Install 3-ply U-channel rails at tube ends and along exposed long edges.

- Corner boards: Run full height—from pallet deck to top cap—with ≥ 3 mm thickness.

- Stacking style: Use column stacking by default. Interlock only if a buyer requires it.

- No mixed heights: Keep every layer uniform. This one rule prevents the most claims.

- Top cap: Cut a full-size cap to match the pallet pattern footprint.

- Strapping: Route straps over the top cap, never directly on carton edges or corners.

- Slip control: Add a slip sheet under layer one if carton bottoms are slick.

- Edge inset: Keep cartons 0.5 in inside the pallet edges to stop film drag and damage.

- Why it matters: These small steps prevent lean, punctures, crushed corners, and clamp damage—saving rework, chargebacks, and your margin.

What Tie/High, Straps, and Stretch Wrap Recipe Makes a Stable Pallet Pattern for U.S. DCs?

When teams guess, patterns drift. Drift brings tilt. Tilt brings damage. A posted Tie×High map with strap and wrap notes ends the guessing.

Publish Tie×High (e.g., 10×6=60). Use 2 poly straps crosswise + 2 lengthwise under the top cap. Wrap 3 passes up + 3 passes down. Twist a wrap “rope” into a pallet notch to anchor the film.

Pallet Pattern and Restraint—Simple Math That Survives the Dock (Target Keywords Inside)

With cartons protected, I publish a clear pallet pattern so the packing line stops guessing:

- Post the map: Put a pallet pattern image at eye level on the line.

- Layer layout: 5×2 cartons, long side along the 48 in; tight pack; 0.5 in inset on all edges.

- Stack height: Six layers standard.

- Protection first: Install 4 corner boards and outside edge rails before strapping.

- Straps: 4 total—2 across + 2 along—so tension crosses both axes; straps sit on the top cap, never on carton edges.

- Film: Use 80-gauge equivalent or better.

- Wrap sequence: 3 passes up to lock corners, 3 passes down to bind to the deck.

- Film anchor: Twist one pass into a rope and press it into a pallet notch.

- Slip control: Add a slip sheet only if carton bottoms are slick.

- Housekeeping: Trim tails; no film dragging on the floor.

- Proof shots: Photograph front/back, label close-ups, strap paths, and the top cap.

A posted map plus this restraint routine turns setup into muscle memory. Loads stay square, labels scan first time, and pallets clear U.S. DCs without rework or chargebacks.

How GS1-128 Carton Labels and SSCC Pallet Labels Reduce Chargebacks in Palletization for U.S. DCs?

Bad labels fail at the dock. Then ASNs do not match. Then debits land. Clear GS1-128 carton label and SSCC pallet label rules stop the pain.

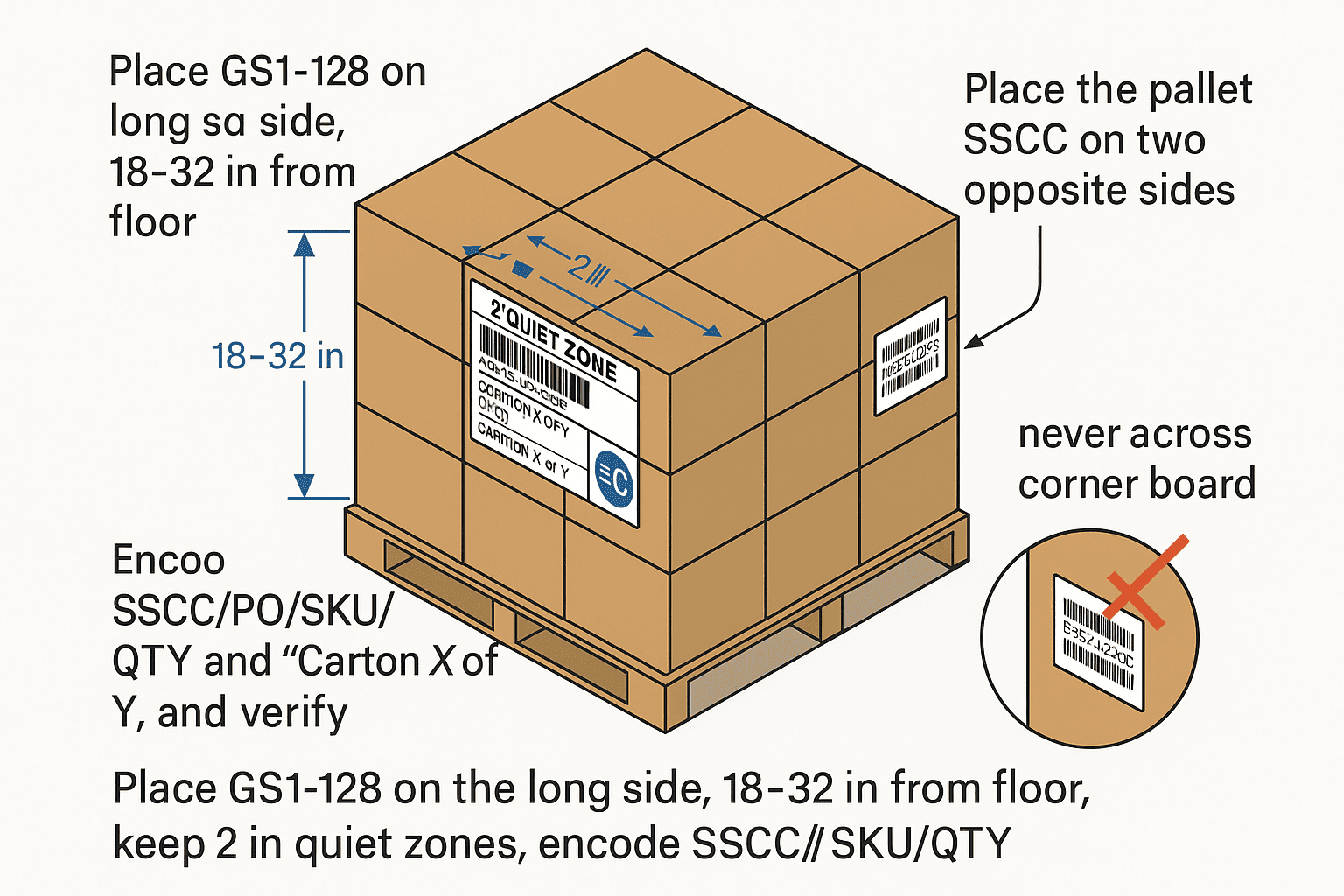

Place GS1-128 on the long side, 18–32 in from the floor, keep 2 in quiet zones, encode SSCC/PO/SKU/QTY and “Carton X of Y,” and verify ≥ C grade. Place the pallet SSCC on two opposite sides, never across a corner board.

GS1-128 Carton Label—Quiet Zones, Placement, and Verification (Target Keywords Included)

With the pallet pattern locked, I make labels scan on the first try:

- Placement (cartons): Mount GS1-128 at 18–32 in from the floor so clamps and scanners align.

- Quiet zones: Keep 2 in of clear space around the barcode for clean reads.

- Materials: Print on matte or light satin to reduce glare; add thin gloss laminate only if transit scuffing occurs.

- Data fields: Encode SSCC, PO, SKU, Quantity, and “Carton X of Y” when required.

- Verification: Achieve ≥ C grade and save the verifier report.

- Placement (pallets): Print the SSCC pallet label and place it on two opposite sides at eye height—never over corner boards or across tear strips.

- Pre-ASN check: Match counts to labels, take photo proof (labels, sides, placement), and file everything in the pack file.

These simple labeling rules prevent mis-scans, align ASNs with physical counts, and remove most scan disputes before they start.

Why Amazon, Walmart, Target, and 3PL Routing Rules Change Palletization for U.S. DCs?

Each account adds rules. Miss one and you pay a debit. Height caps, appointments, and clamp handling show up again and again.

For Amazon FCs, keep pallet height ≤72 in and zero overhang. For big-box DCs, book appointments, align ASN counts, and protect with top caps and corner boards because clamp handling is common.

Account-Specific Pallet Pattern and Label Nuances (Include Target Keywords)

With labeling dialed in, I follow account-specific rules to avoid surprise debits and delays:

-

Amazon FCs

- Height cap: Keep total pallet height ≤ 72 in (including pallet).

- Zero overhang: Not even 5 mm—stay inside 40×48.

- SIOC/Overbox: Follow parcel DTC rules, then still palletize for clamp trucks at the FC.

-

Walmart / Target / Costco / 3PLs

- Appointments: Treat booking as part of the quality plan.

- ASN accuracy: Match carton and pallet counts line-by-line before release.

- Clamp handling expected: Always use corner boards, a full top cap, and four straps.

- Scan ergonomics: Keep label heights consistent so dock teams scan without bending.

- Documentation: Store each routing guide with the PO and note exceptions on the pallet map page.

When the pallet meets each retailer’s playbook—height, overhang, clamps, labels, and paperwork—trucks unload on time, ASNs clear without chargebacks, and margins stay protected.

What Does ISTA 3E Prove About Unitized Loads for Camping Furniture Manufacturers in China?

Opinions end. Test data wins. ISTA 3E exposes loose straps, weak corners, and hidden lean before the DC does. A pilot pallet is cheap insurance.

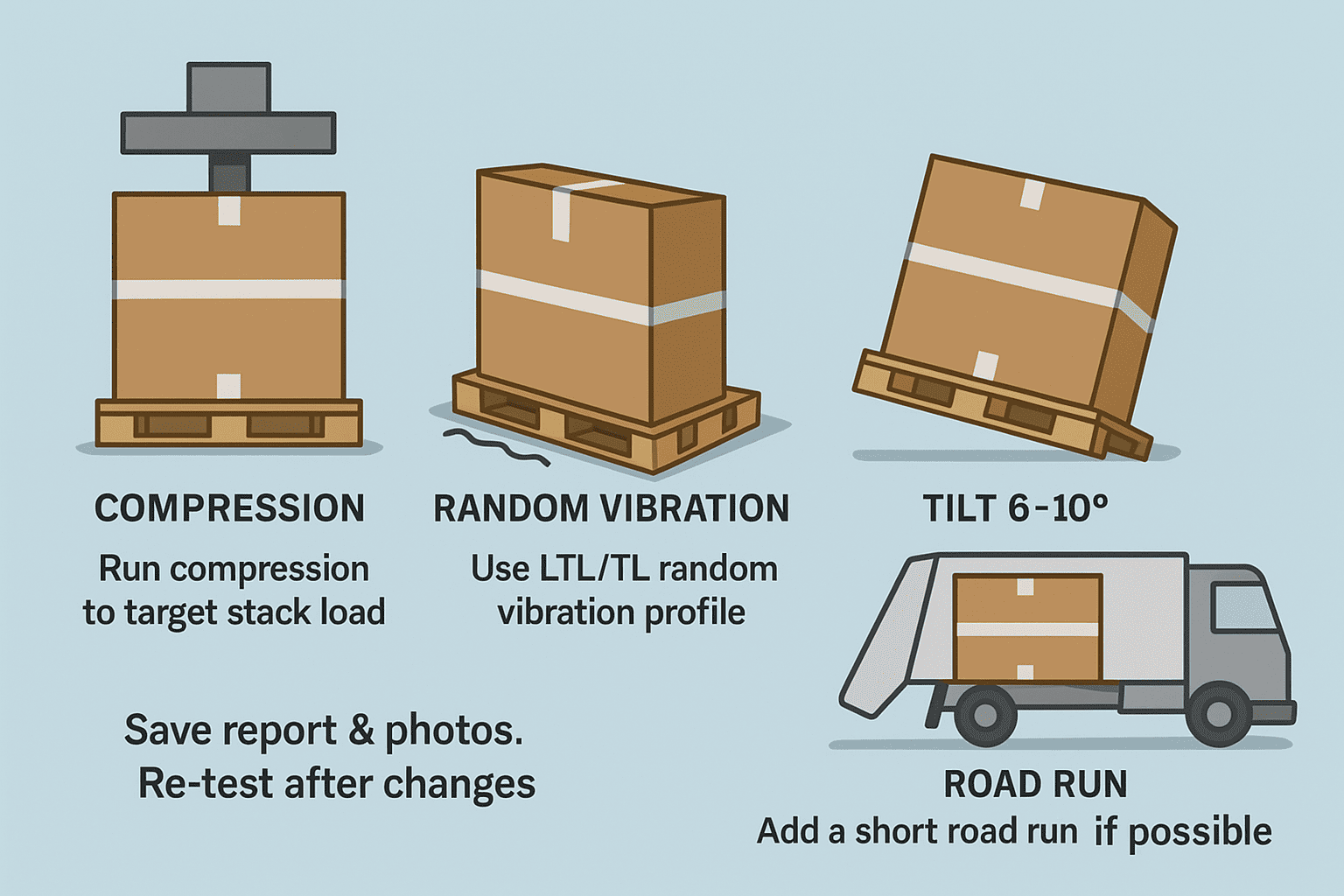

Run compression to the target stack load, use the LTL/TL random vibration profile, tilt 6–10° for lean risk, and add a short road run if possible. Save the report and photos. Re-test after any carton or cushioning change.

ISTA 3E—Simple Plan, Strong Results

Moving from retailer rules to proof, I use ISTA 3E to validate the whole unit load before scale-up:

- Compression: Calculate the DC’s planned stack height and test to that stack load.

- Random vibration (LTL/TL): Run the carrier profile to expose settling and strap loosening.

- Incline/Tilt: Test at 6–10° to reveal lean risk and weak corners.

- Road simulation: When possible, do a short over-the-road loop with the actual carrier.

- Measurements: Record before/after dimensions, strap tension, corner board condition, and label scan results.

- Documentation: Attach the report + photo set to the pack file and link them in the PO.

- Re-validation triggers: Re-test after any change in carton size, foam/cushioning, or pallet source.

This is not red tape. ISTA 3E gives hard evidence that our palletization for U.S. DCs will be scanned, stacked, and paid—without debates at the dock.

Why Simple Do/Don’t Rules Cut Damage for Camping Furniture Palletization (Edge Rails, Corner Boards, Pallet Pattern)?

Small mistakes repeat under pressure. I remove them with a short list teams can follow at speed.

Do use edge rails at tube ends, bag metal feet, standardize pallet patterns by SKU family, and add orientation icons. Do not mix heights, stack past 72 in without approval, place hand holes on clamp faces, or let straps bite into corrugate.

Fast Checks That Stop Slow Losses (Target Keywords Added)

To turn rules into habits on the floor, I use a simple do/don’t list for camping furniture manufacturers in China:

Do

- Install U-channel edge rails where tubes meet corrugate.

- Bag metal feet/caps to prevent scuffs and punctures.

- Post standard pallet patterns (Tie×High, strap paths, wrap count) at eye level.

- Add clear “This Side Up/Do Not Stack” icons on outer cartons.

Don’t

- Mix heights on the same pallet—ever.

- Stack over 72 in without written buyer approval.

- Cut hand holes on faces that meet clamps or forks.

- Let straps bite into cartons; always use a top cap.

Execution aids

- Photo each step and tape images beside the line—pictures beat text.

- Do a quick pre-ship walkaround: edges protected, labels outward, straps on the top cap, film tails trimmed.

- Keep a one-page SOP with the pallet map, label placements, and refusal triggers.

This short checklist keeps teams fast and consistent. Claims drop, DC refusals fade, and trucks stop boomeranging back to the factory.

What Really Gets Loads Refused at U.S. DCs—and How to Prevent It with Palletization for U.S. DCs?

Refusals feel random until patterns appear. The same five problems loop: ASN mismatches, overhang, leaning stacks, dirty pallets, and unreadable labels.

Fix counts before ASN release, keep zero overhang, hold column stacks with uniform heights, use A-grade pallets only, and verify GS1-128 to grade C or better. Attach photo proof to every ASN.

From Refusal to Release—My Photo SOP (Keywords Inside)

To close the loop between what we ship and what the DC receives, I bind every ASN to clear photo proof:

- Full views: Take front and back shots of each pallet.

- Label close-ups: Capture GS1-128 carton labels and SSCC pallet labels so data is readable.

- Restraint details: Photograph strap paths over the top cap to show straps are not cutting cartons.

- Protection details: Shoot corner boards and edge rails to confirm correct installation.

- Footprint check: Include a ruler photo proving the load sits inside the 40×48 pallet.

- Filing: Save all images in the pack file under the PO number.

- Sending: Email a compressed photo set with the ASN so the receiver has it before booking.

When the ASN travels with photo evidence, everyone sees the same facts. Disputes shrink, approvals move faster, and weekly shipments clear with less noise.

Why Copy-Ready PO Clauses Keep Palletization for U.S. DCs on Track—Edge Rails, Corner Boards, GS1-128, and ISTA 3E?

Verbal rules vanish at 2 a.m. on a loading dock. Short PO clauses lock the standard and speed training across shifts and factories.

Paste these: pallet standard, protection set, labeling, pallet pattern, testing, and ASN match. Short lines, clear words, enforced with photos.

PO Language You Can Use Today (All Target Keywords Present)

To lock daily practice into every order, I use six short, copy-ready PO clauses:

- Pallet standard: “Use 40×48 in 4-way HT GMA pallets; no overhang. A-grade only.”

- Protection: “Add corner boards, edge rails, and top cap; strap 4× (2 cross + 2 length), wrap 6× with rope anchored into pallet.”

- Labeling: “Apply GS1-128 carton label with ≥ C grade and 2 in quiet zone; pallet SSCC on 2 sides.”

- Pattern: “Load per buyer pallet pattern (Tie × High). Mixed heights prohibited.”

- Testing: “Supplier maintains ISTA 3E unitized-load PASS; any pack change requires re-validation.”

- ASN match: “ASN counts must match shipped pallet/carton counts; mismatch costs charged back to supplier.”

Execution aids:

- Paste clauses in English and Chinese.

- Bold key phrases for quick scanning.

- Attach a one-page photo SOP (pallet map, label placement, strap/wrap examples).

These tight clauses make expectations visible, train teams fast, and cut disputes—so pallets load right, ASNs clear, and margins stay protected.

FAQ — Palletization for U.S. DCs (Rewritten Answers)

Q1: Why is “no overhang” a hard rule?

Because overhang moves compressive load to weak carton edges and corners. It also catches on clamps and conveyors. Many U.S. DCs treat any overhang as a compliance failure, which can trigger debits or refusal.

Q2: Column or interlock stacking—which is better?

Column stacking is stronger in compression and keeps stacks plumb. Use interlock only when a retailer’s routing guide requires it or when stability testing proves it necessary.

Q3: What pallet spec should I lock for U.S. DCs?

A 40×48 in GMA pallet with true 4-way entry, HT stamp, seven top deck boards, A-grade condition, flush nails, and a static rating of at least 2,000 lb. Confirm any double-stack plan with the buyer and carrier.

Q4: Edge rails vs. corner boards—do I need both?

Yes for camping furniture. Corner boards resist clamp and strap pressure; edge rails protect long edges and tube ends from puncturing corrugate. Together they cut crush and rub damage.

Q5: How do I publish a pallet pattern (Tie × High)?

Create a one-page map showing layer layout, Tie × High, strap paths, and wrap count. Post it at eye level on the line and attach the PDF/PNG to the PO and pack file.

Q6: What strap/wrap recipe works?

Four straps total—two across and two along—run over a full top cap. Use about 80-gauge equivalent stretch film: three passes up, three down, with one pass twisted into a rope and anchored into a pallet notch.

Q7: GS1-128 carton label—what are the key rules?

Place the symbol on the long side at 18–32 in from the floor, keep 2 in quiet zones, encode SSCC/PO/SKU/Qty (and Carton X of Y if required), and verify at grade C or better.

Q8: Pallet SSCC label—where does it go?

On two opposite sides at eye height, never across corner boards or tear strips. Keep it clean, flat, and scannable.

Q9: What causes common refusals at U.S. DCs?

ASN mismatches, overhang, leaning stacks from mixed heights, dirty or broken pallets, and low barcode grades. Fixes are accurate counts, column stacking, A-grade pallets, and verified labels.

Q10: Any Amazon-specific notes?

Stay at or under 72 in total height including the pallet and avoid any overhang. For SIOC/overbox parcels, follow DTC rules but still palletize to survive clamp handling at fulfillment centers.

Q11: When should I run ISTA 3E?

At launch, when suppliers change, or when carton, cushioning, or pallet sources change. Run compression to planned stack load, LTL/TL random vibration, and 6–10° tilt; keep the report and photos.

Q12: Slip sheets—when to use them?

Use one under the first layer when carton bottoms are slick or when tests show load shift. Skip it when friction is already sufficient.

Q13: CHEP/PECO/iGPS—how should I handle program pallets?

Use them only if the buyer mandates the pool. Update the PO, pallet map, and factory training to match that program’s specs.

Q14: How do I prevent straps from cutting cartons?

Install a full top cap and corner boards before strapping. Route straps over the cap, not directly on carton edges, and tension to spec rather than “as tight as possible.”

Q15: What photo proof should travel with the ASN?

Front and back pallet shots; close-ups of GS1-128 and SSCC; images of strap paths over the top cap; details of corner boards and edge rails; and a ruler photo proving the load is inside 40×48. File under the PO and send a compressed set with the ASN.

Q16: How tall can I stack if not specified?

Default to 72 in including the pallet unless the buyer approves a higher limit in writing. Confirm carrier and DC stacking rules before shipping.

Q17: What belongs in copy-ready PO clauses?

The pallet standard, protection set (corner boards, edge rails, top cap), strap/wrap recipe, GS1-128/SSCC labeling, pallet pattern (Tie × High), ISTA 3E requirement, and the ASN match clause.

Q18: What’s the fastest checklist for camping furniture makers in China?

40×48 HT GMA pallets (A-grade), zero overhang, column stack with uniform layers, corner boards + edge rails + top cap, four straps + six wraps with a rope anchor, GS1-128 grade C or better, pallet SSCC on two sides, pallet map posted on the line, photo SOP tied to the ASN.

Conclusion

Get the pallet right. Add edge rails and corner boards. Label clean with GS1-128. Prove it with ISTA 3E. Publish the pallet pattern. Photo-verify and ship once.

If you want palletization that survives U.S. DCs, visit www.kingrayscn.com or email Lisa Wang at marketing@kingrayscn.com to schedule a quick consultation and get a copy-ready pallet spec.